Test Nacelle Equipment

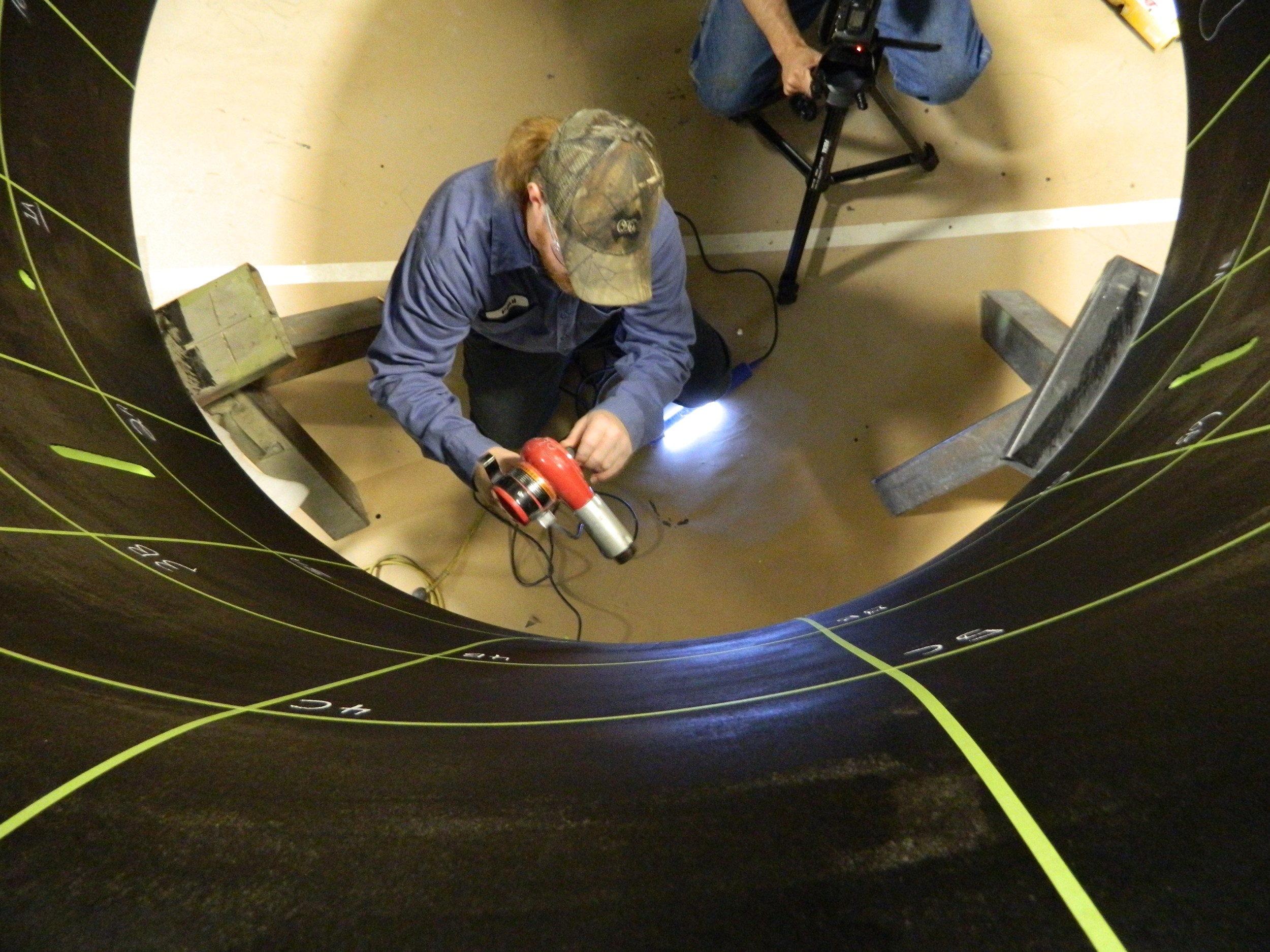

Phoenix Composite Solutions, LLC has been in the Test Nacelle Business for the past 7 years. Our capabilities allow us to perform 98% of the work necessary to produce any Nacelle or Bellmouth System in-house. Our largest autoclave, (13 FT Diameter x 42 FT Long) can handle most Nacelle and Bellmouth needs. We also have our own tooling and machine shops for all of our detail needs.

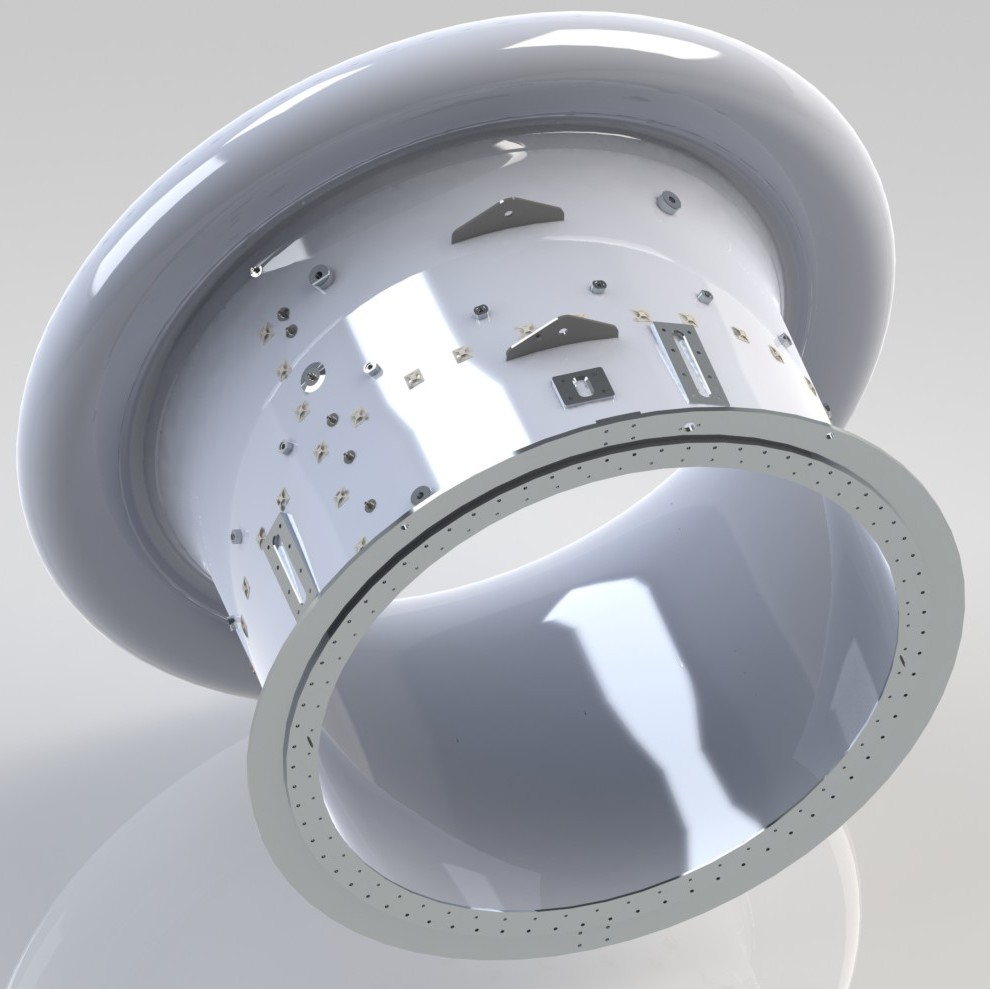

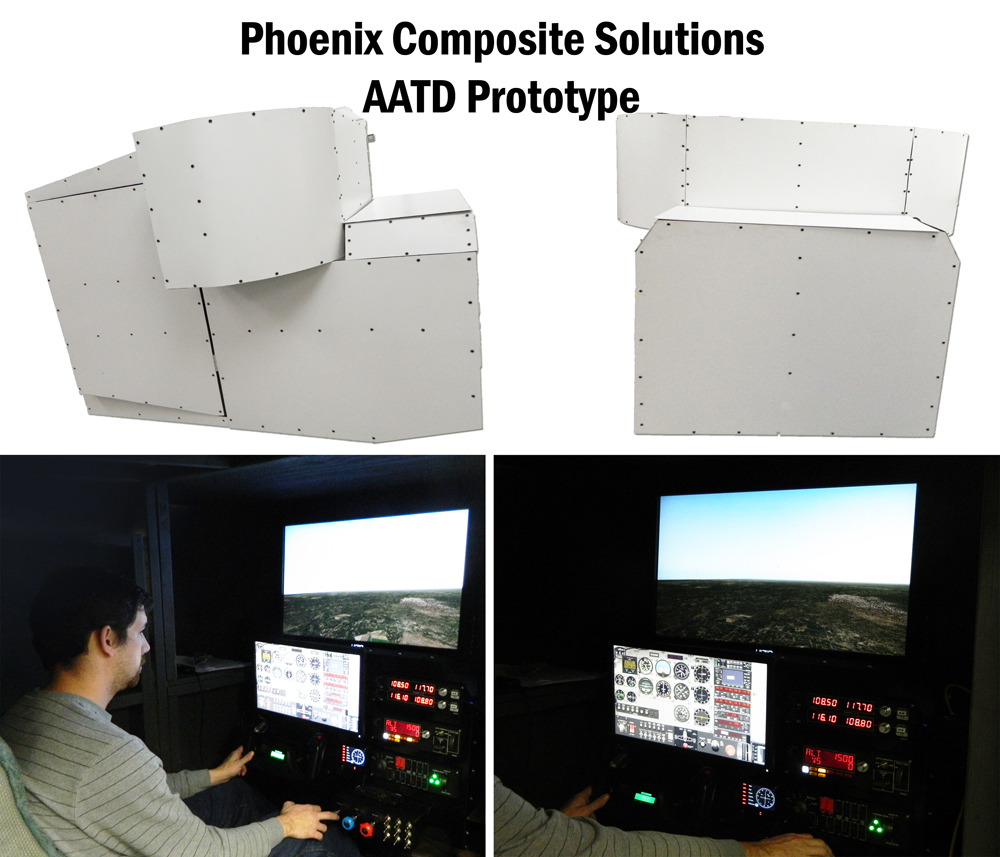

Test Nacelle Equipment, part of our OEM Division designs, develops, analyzes, and manufactures a wide selection of Bellmouths, Storage systems, and slave thrust reversers for some of the world's largest engine manufactures and MRO's.

Our many years of collective knowledge in the Nacelle Industry and in the Aviation Community, serve us well. We have been on the receiving side of this business, so we understand our customer's needs. Our core competencies are comprised of not only advanced composites, but also metal structures. This allows a hybrid approach to all legacy and new design projects. OEM also has dedicated project management, design engineering, and structural analysis capabilities. We are a complete solutions provider.

We have 3 facilities that support the TNE activities. Our main plant is a 106,000 square foot facility. This facility is where most of our heavy equipment resides. Our large clean rooms and autoclave processes are performed here. We have an 8,000 square foot facility that handles special machining, water jet cutting, heat treating and special fabrication. Our assembly plant is 35,000 square feet. The assembly plant is where we do all special processes, jig/fixture work, finishing, and painting operations.

Phoenix Composite Solutions is capable of producing large parts, very accurately, using our custom machining center. It can produce tight tolerance parts that are up to 84" tall, with 132" outer diameters. It's inner diameter capabilities currently range from 55" to 90". This custom machining center is also configurable to allow it to accept larger or smaller parts.

Phoenix Composite Solutions also utilizes 3-D Printing. PCS has just cut printing costs down to a fifth, by buying a larger printer with many new materials. Please see the new materials during quoting. PCS will be adding more materials as we finish fine tuning the settings.

Keep in mind that you can upload any 3d print/model you find on any model sharing website. In the event you have your own model to print, but need an STL file, you can e-mail it to PCS at erick.martin@phoenix-mi.com. We can take your generic CAD model (STP, IGS, XB), and return an STL file. PCS is familiar with non disclosure agreements in case the project you want to print is proprietary. PCS also has a variety of CAD and FEM software if your seeking a engineering service to help bring your idea to life

Click here and use PCS to print your prototype, master mold or functioning model today.

Note: We currently print using ABS (maximum build size per segment is 5x5x5”) We will be adding PLA, Polycarbonate, Nylon, PLA with Bronze/Copper/Aluminum/Stainless Steel/ Carbon Fiber/ Carbon Fiber Nanotubes, Bendlay Rubber, and several types of wood shortly. (build size per segment is 12x8x10”)! When our new printer is online, each material will be listed along with their respective prices.